Causes for increased optical damping:

|

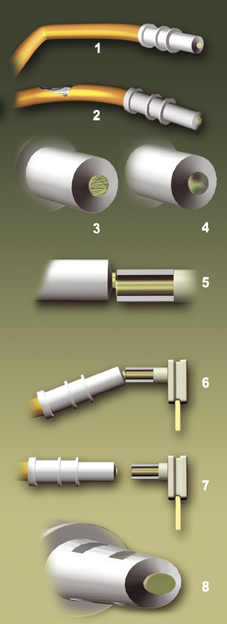

- Bending radius too small, kink (e.g. incorrect installation)

- The covering of the FOC is damaged (e.g. hot parts near the FOC)

- Scratched end surface (e.g. by improper cutting tool)

- Soiled end plane (e.g. careless handling)

- End surfaces lie offset to each other (e.g. incorrect plug connector)

- End surfaces lie slanted to each other (e.g. damaged plug connector)

- Gaps between the end surfaces (e.g. due to the plug connector not being engaged)

- FOC squeezed (e.g. inappropriate crimping)